Gidravlik to'sar chiselli ekskavator to'mtoq xanjar olmos nuqtasi

Chisel tavsifi

Afzal xomashyo yetkazib beruvchilar uchun 40Cr va 42CrMo materiallari yuqori sifatli tanlov hisoblanadi.Ikkala material ham yaxshi mexanik xususiyatlarga va chidamlilikka ega va yuqori quvvat va yuqori aşınma qarshilik talab qiladigan ba'zi ilovalar uchun javob beradi.Issiqlik bilan ishlov berish nuqtai nazaridan, maxsus takomillashtirilgan issiqlik bilan ishlov berish uskunalari materiallarning sifati va ishlashini ta'minlash uchun ilg'or jarayonlar va uskunalardan foydalanishi mumkin.Beshta issiqlik bilan ishlov berish jarayoni, shu jumladan ikkita bosqichli temperleme orqali, qotib qolgan qatlamning chuqurligini samarali oshirish va materialning qattiqligi va chidamliligini oshirish mumkin.Shu tarzda mahsulotning xizmat qilish muddatini 30% dan 80% gacha oshirish mumkin.Ushbu yaxshilanishlar 40Cr va 42CrMo materiallarini yanada mustahkam va barqaror qilishi mumkin.Xom ashyo yetkazib beruvchilarni tanlashda materiallar yuqori sifatli va standartlarga javob berishiga ishonch hosil qiling, shu bilan birga takomillashtirilgan issiqlik bilan ishlov berish jarayonlari materialning ish faoliyatini yanada yaxshilashi mumkin.

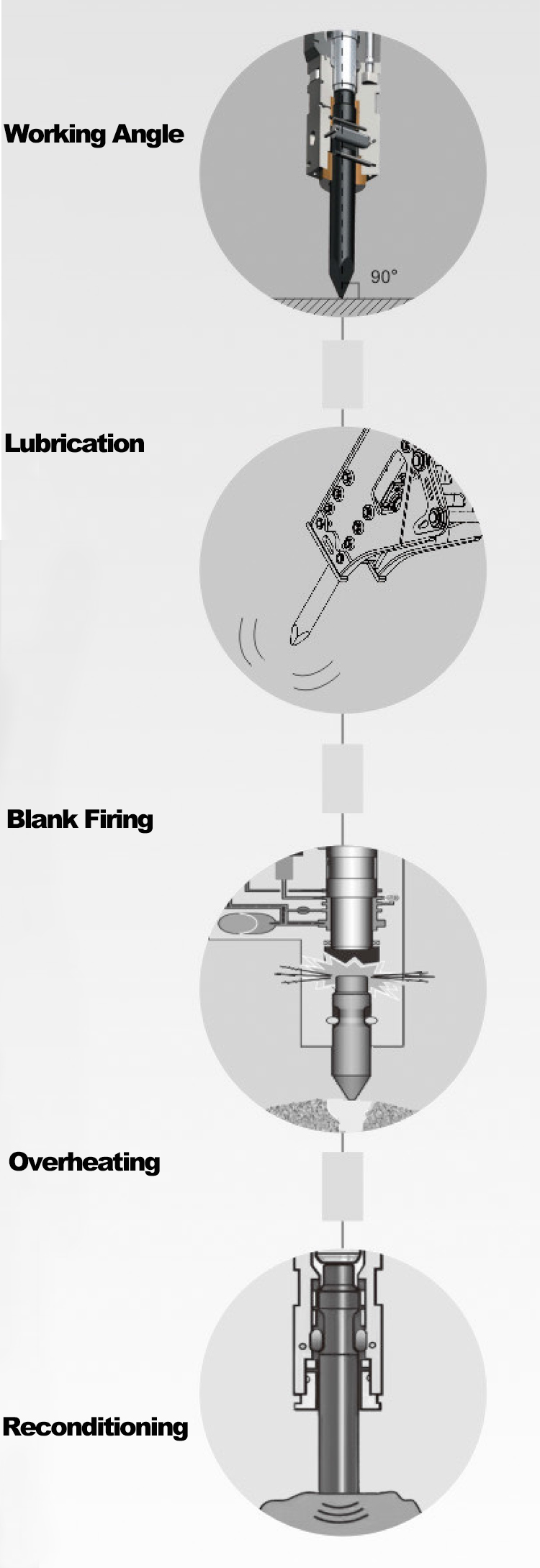

Ishlash burchagi

Vertikal zarba operatsiyasi Rodning xizmat qilish muddatini ta'minlash uchun novda va ish joyini 90 ° burchakka perpendikulyar qilish to'g'ri.Agar burchak noto'g'ri bo'lsa, novda va vtulka o'rtasida yuqori bosim paydo bo'ladi, bu esa aloqa yuzalarida aşınma va novda yoki novda shikastlanishiga olib keladi.Eskirgan butalar novda egilishiga va keyinchalik pistonning shikastlanishiga olib kelishi mumkin.

Moylash

moylash Rod va vtulka orasidagi aloqa joyini moylash uchun muntazam ravishda yuqori sifatli yuqori haroratli va yuqori bosimli moylash moyidan foydalaning.Noto'g'ri ish usullari, masalan, burchak ostida urish, ob'ektni tortish yoki haddan tashqari egilish, aloqa yuzalarida yuqori kuchlanishlarni keltirib chiqarishi mumkin.Yog'lar yaxshi himoya qiladi va xizmat muddatini uzaytiradi.

Bo'sh otish

Quruq zarba Quruq zarbalar novda ish yuzasiga to'liq tegmasa, singan narsaga sirpansa yoki ob'ekt juda yumshoq yoki ingichka bo'lganda paydo bo'lishi mumkin.Rod ushlagichga urilishi mumkin va zarba kuchi pinning qattiq aşınmasına yoki sinishiga olib kelishi mumkin.Ustunni muntazam ravishda tekshirish tavsiya etiladi, tercihen har 30-50 soatda, buzilishlarni tekshirish va kamchiliklarni bartaraf etish.Bundan tashqari, burmalarni eskirish yoki shikastlanganligini tekshiring va kerak bo'lganda almashtiring yoki ta'mirlang.

Haddan tashqari qizib ketish

Harorat juda yuqori va qo'ziqorin hodisasi paydo bo'ladi Bir pozitsiyani 10-15 soniyadan ko'proq vaqt davomida doimiy ravishda urishdan saqlaning.Ob'ektni buzmasdan uzoq vaqt urish klub boshi ichida issiqlik tarqalishini oldini oladi.Haddan tashqari issiqlik paydo bo'lganda, tayoqlar dekarblanishi va yumshoq bo'lib qo'ziqorin paydo bo'lishiga yoki to'planishiga olib kelishi mumkin.Natijada, rodning xizmat qilish muddati qisqartiriladi yoki uni yirtib tashlash kerak bo'lishi mumkin.

Qayta tiklash

Muntazam parvarishlash Odatda, novda ta'mirlashni talab qilmaydi.Shu bilan birga, boshning deformatsiyasi novda va to'sar o'rtasidagi butun aloqa yuzasida yuqori kuchlanishlarni keltirib chiqaradi.Uni frezalash yoki burish orqali ta'mirlash tavsiya etiladi.Payvandlash yoki olovni kesish tavsiya etilmaydi, chunki hosil bo'lgan issiqlik materialning strukturaviy o'zgarishiga olib kelishi va aşınmayı tezlashtirishi mumkin.

Chisel modeli biz etkazib bera olamiz

| Ekskavator chiseli | |||||||

| Material: 42crmo | |||||||

| Model | Dia | Uzunlik | Og'irligi | Model | Dia | Uzunlik | Og'irligi |

| SOOSAN | FURUKAVA | ||||||

| SB43 | 75 | 740 | 23 | HB100 | 55 | 500 | 9 |

| SB50 | 100 | 1050 | 58 | HB200 | 70 | 510 | 13 |

| SB60 | 120 | 1050 | 91 | HB700 | 104 | 940 | 49 |

| SB70 | 135 | 1200 | 117 | HB1G | 36 | 400 | 3 |

| SB80 | 140 | 1200 | 130 | HB2G | 45 | 460 | 4 |

| SB120 | 155 | 1450 | 193 | HB3G | 60 | 560 | 11 |

| SB121 | 155 | 1450 | 193 | HB5G | 75 | 650 | 20 |

| SB130 | 165 | 1500 | 227 | HB10G | 105 | 1000 | 65 |

| SB130-3 | 155 | 1500 | 185 | HB15G | 120 | 1000 | 80 |

| SB150 | 175 | 1600 | 272 | HB30G | 150 | 1300 | |

| SB160 | 175 | 1600 | 272 | F-1 | 36 | 400 | 3 |

| SH200 | 70 | 600 | 16 | F-2 | 45 | 480 | 5 |

| SH400 | 95 | 840 | 40 | F-3 | 52 | 520 | 8 |

| SH700 | 105 | 930 | 55 | F-4 | 60 | 540 | 11 |

| SH18G | 120 | 1110 | 85 | F-5 | 68 | 610 | 16 |

| SH20G | 135 | 1200 | 120 | F-6 | 75 | 720 | 23 |

| SH30G | 150 | 1300 | 157 | F-9 | 90 | 800 | 32 |

| SH35G | 140 | 1300 | 137 | F-12 | 105 | 1000 | 66 |

| SH40G | 160 | 1400 | 192 | F-19 | 120 | 1100 | 86 |

| SH50G | 180 | 1515 | 263 | F-22 | 135 | 1200 | 117 |

| SB30 | 53 | 580 | 9 | F-35 | 150 | 1400 | 169 |

| KRUPP | INDECO | ||||||

| HM130/131/135/140V | 65 | 780 | 18 | MES180/181/200 | 48 | 550 | 6 |

| HM300/301/305 | 80 | 900 | 30 | MES300/301/350/351 | 55 | 600 | 10 |

| HM170/185/190V | 75 | 800 | 25 | MES451/521/550/HB5 | 65 | 650 | 14 |

| HM550/560CS/V | 100 | 1000 | 55 | MES601/621/650 | 80 | 650 | 22 |

| HM700/720CS/V | 115 | 1080 | 82 | MES1200-HB12 | 90 | 800 | 34 |

| HM900/901/902 | 135 | 1150 | 115 | MES1500/HB19 | 110 | 900 | 55 |

| HM950/960/SC/V | 135 | 1080 | 110 | MES1750/1800 | 114 | 1000 | 72 |

| HM1300/1500CS/V | 150 | 1200 | 151 | MES121/150 | 45 | 480 | 5 |

| HM1800/2000CS/V | 160 | 1400 | 220 | MES2000/HB27 | 120 | 1000 | 78 |

| HM2200/2500CS/V | 180 | MES2500 | 130 | 1100 | 101 | ||

| HM45 | 42 | 470 | 6 | MES3000 | 140 | 1200 | 130 |

| HM50/55 | 45 | 480 | 7 | MES3500 | 145 | 1300 | 155 |

| HM60/75 | 55 | 590 | 10 | MES4000 | 150 | 1300 | 160 |

| HM85/90 | 62 | 600 | 11 | MES5000 | 160 | 1350 | 190 |

| HM100/101 | 65 | 700 | 18 | MKB | |||

| HM200 | 80 | 785 | 27 | MKB1300N | 135 | 1150 | 116 |

| HM400/401 | 80 | 800 | 27 | MKB1400 | 135 | 1150 | 116 |

| HM600/601 | 100 | 1000 | 55 | MKB2000 | 150 | 1250 | 156 |

| HM800 | 135 | 1150 | 115 | MKB2000N | 149 | 1250 | 154 |

| HM1200 | 120 | 1250 | 155 | MKB2500 | 160 | 1350 | 185 |

| GUANGLIN | MKB3000 | 165 | 1500 | 227 | |||

| SG1800 | 135 | 1200 | 120 | MKB4000N | 180 | ||

| SG2100 | 138 | 1250 | 125 | MKB100 | 45 | 450 | 5 |

| Model | Dia | Uzunlik | Og'irligi | Model | Dia | Uzunlik | Og'irligi |

| GUANGLIN | MKB | ||||||

| SG2500 | 145 | 1300 | 151 | MKB150 | 55 | 600 | 10 |

| SG2800 | 155 | 1450 | 190 | MKB200 | 65 | 600 | 14 |

| SG3200/3300 | 158 | 1500 | 200 | MKB300N | 70 | 750 | 20 |

| SG5000 | 180 | 1600 | 280 | MKB400 | 80 | 600 | 21 |

| SG200 | 45 | 500 | 5 | MKB500 | 80 | 600 | 21 |

| SG300 | 57 | 600 | 10 | MKB800 | 100 | 1000 | 55 |

| SG350 | 68 | 700 | 17 | MKB900N | 100 | 1000 | 55 |

| SG400 | 75 | 690 | 20 | MKB1200 | 115 | 1150 | 84 |

| MONTABERT | DAENO | ||||||

| BRH75/76/90/91 | 60 | 550 | 8 | DMB03 | 68 | 600 | 16 |

| BRP85/100 | 62 | 620 | 12 | DMB04 | 95 | 900 | 43 |

| BRP130/150 | 75 | 740 | 21 | DMB06 | 105 | 930 | 55 |

| BRV32 | 122 | 1100 | 90 | DMB4000 | 150 | 1450 | 181 |

| BRV43 | 150 | 1300 | 160 | DMB5000 | 165 | 1600 | 249 |

| BRV45 | 150 | 1300 | 160 | S150 | 57 | 600 | 10 |

| BRV52 | 162 | 1350 | 192 | S500 | 69 | 680 | 18 |

| BRV53 | 170 | 1400 | 230 | S900 | 85 | 830 | 33 |

| BRV55 | 170 | 1500 | 245 | S1300 | 105 | 926 | 56 |

| BRV1600 | 140 | S1800 | 120 | 1000 | 80 | ||

| BRH40 | 45 | 500 | 6 | S2200-1 | 130 | 1200 | 112 |

| BRH125 | 80 | 700 | 21 | S2000-2 | 135 | 1200 | 121 |

| BRH250/270 | 95 | 850 | 40 | S2500 | 140 | 1200 | 130 |

| BRH501/570 | 114 | 1000 | 76 | S3000/3600/4500 | 150 | 1350 | 168 |